|

| February 11, 2014 | Volume 10 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Real-World 3D Printing:

Cleveland Golf drives home new designs

Cleveland Golf, founded as Cleveland Classics in 1979, has come a long way since the days of producing replica golf clubs. Headquartered in Huntington Beach, CA, the international company (owned by Dunlop Sports Co. Ltd.) now designs and manufactures its own wedges, woods, drivers, and other golf equipment and has affiliates in three countries and a presence in over 20 others, while maintaining a strong sponsorship of champions. The company was the first to market wedges with multiple bounce options on the sole and individually mill grooves into wedge faces.

In order to keep up with its strong heritage while also having a mind for the future, Cleveland Golf invested in additive manufacturing during the early millennium.

Dan Nivanh, the research and development engineer at Cleveland Golf who is responsible for running the company's ULTRA machine, uses the ULTRA along with two other printers to complete rapid prototyping of club heads. According to Nivanh, the company began using 3D printing to cut production costs, but their Objet printer was not allowing them to complete tasks efficiently. Nivanh sends the builds to a vendor who then makes the final cast. They use Siemens PLM NX, a CAD/CAM software solution, to design the prototype before running the file through Magics to print.

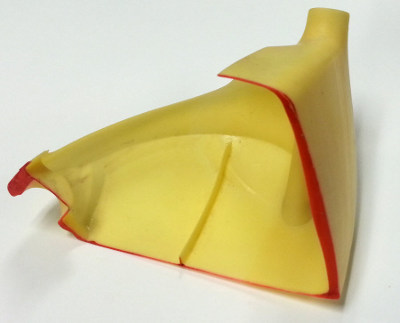

Nivanh and his team at Cleveland Golf verifiy their designs by looking at cross-sectional samples that physically show the design's intent.

"We use a model mainly to verify a lot of the designs. We try to use it to prototype the actual part itself, too, to make it castable," Nivanh says.

When Nivanh began working at Cleveland Golf, R&D had a plastic ProJet printer from 3D Systems and a Stratasys Dimension 3D printer for wax models. "[Because of] the amount of printing that we do, we needed another printer to take some of the load off of the plastic printer, the ProJet itself," Nivanh says.

"The ProJet was not as reliable -- it was down maybe two times a week -- so we needed to look into another printer which was less maintenance and wouldn't break down as much as the ProJet does," says Nivanh. The main problem with the production process at the company was that the downtime on printers meant the team had to send their prints to an independent contractor. "The downtime was crucial to approve the parts." This indirect processing due to printer problems frustrated Nivanh until he decided to attend the Pacific Design & Manufacturing Tradeshow in Anaheim, CA. There he met an EnvisionTEC sales representative and learned about the functions, reliability, and print quality of the ULTRA family of printers.

"From what I saw [in Anaheim], the quality of the print was very clean, which is what we've liked to put on our models, without having to do any preparation, like sanding it and prepping the surface," Nivanh says.

Nivanh chose the ULTRA for the quality of the finished parts in addition to feeling comfortable with the technology. "With the ULTRA, the user is able to debug some of the problems [with a prototype] on-site, and able to talk to the tech and walk through it and have the problem fixed in a couple of hours, versus having a tech guy come out here and spend all day on the actual printer trying to get it up and running again. I guess once the user understands the function of the printer, they're able to diagnose the problem itself on-site, so by not having multiple moving parts it tends not to break as often as most printers."

Nivanh finds that the ULTRA not only performs better than he expected, it also performs better than the main printer he and his team had been using, a ProJet machine. Nivanh is also pleased with his experience with tech support, though he needed minimal assistance due to the machine's performance. He believes that the minimal moving parts on the ULTRA is what causes his prototypes to materialize with fewer design problems. "Four years later and it hasn't broken down yet," he says. R&D at Cleveland Golf renders and prototypes club heads and drivers through the EnvisionTEC system. Not only does the team trust a machine to do work where other printers fail, but they also were able to harness a very precise, accurate technology entirely to the benefit of their production process.

VIDEO caption: EnvisionTEC's ULTRA 3SP 3D printer.

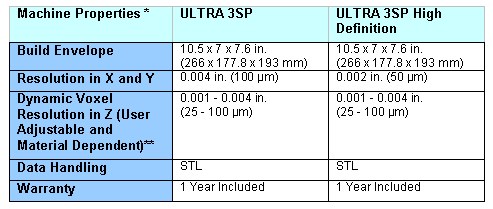

About the ULTRA 3SP and 3SP High-Definition printers

EnvisionTEC's ULTRA 3SP Series 3D printers use ground-breaking 3SP (Scan, Spin, and Selectively Photocure) technology to quickly 3D-print highly accurate parts from STL files, regardless of the geometric complexity. The ULTRA 3SP and 3SP High-Definition are each delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models shows no signs of stairstepping on the inner and outer surfaces. The reliability of the imaging light source and the high-speed productivity make it a highly competitive 3D printer in the market today.

* Specifications are subject to change without notice. ** A voxel is a volumetric pixel. A single material called E-Denstone is used for both build and support.

Source: EnvisionTEC

Published February 2014

Rate this article

View our terms of use and privacy policy